I would like to bring to the reader’s attention the invention of the bottle-sealing device, more commonly known as the metal cap. As a result of this invention the beverage industry grew at an unprecedented rate and made possible the joy and convenience of having a fizzy drink at home while watching movies or shows. The significance of the bottle-sealing device is invaluable because without the bottle sealing device, beverages would’ve been enjoyed only at pubs and restaurants, and perhaps television and streaming would not have become as widespread and popular as they are today. The bottle-sealing device was an invention of a humble mechanical engineer, named William Painter, who was born in Ireland in 1838. He immigrated to the United States when he was twenty years old in pursuit of opportunities to make wealth. He settled down in Baltimore, Maryland, and it was there where he was awarded a patent for the bottle-sealing device and later related patents.[i]

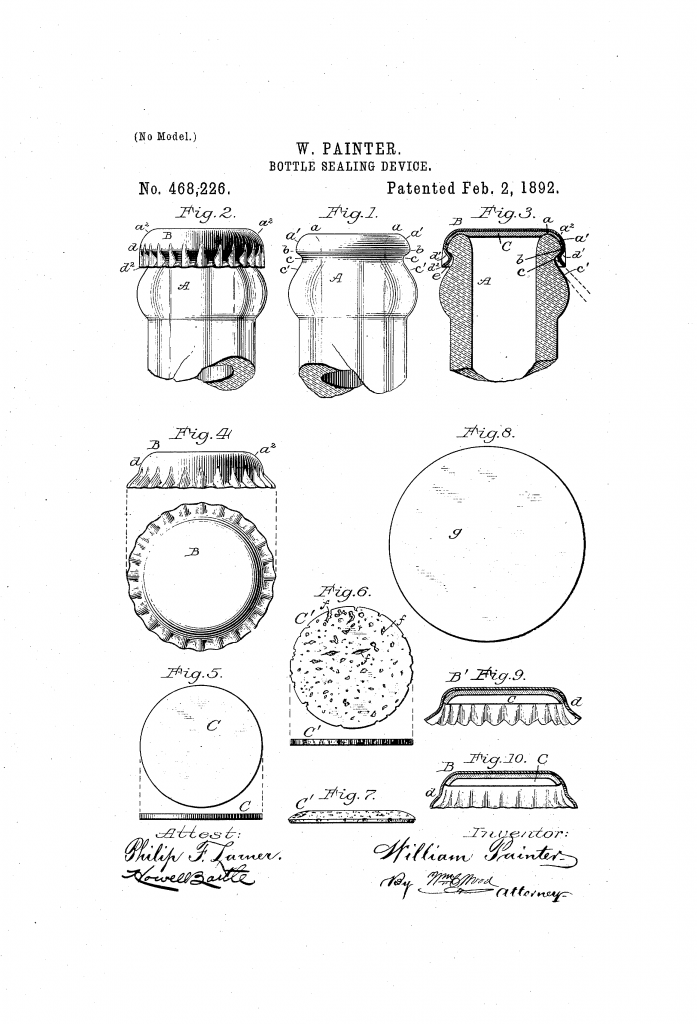

Painter used figures to illustrate each part of the bottle-sealing device: a metal cap, a sealing disk, and the bottle itself before and after they were sealed, which made comprehending his invention much easier and more interesting to look at. The metal cap was in the form of a flange with ridges at the bottom. From the figures used, the metal cap was locked in place with the sealing disk underneath it, and the disk, at its edges, was compressed between the metal cap and the ring shaped bottle lip. Also, there was a figure of how the sealing disk looked like before and after it was compressed between the bottle head and the metal cap. As simple as it may sound on paper, Painter came across a few issues along the way to invent the bottle sealing device.

One was with the shape of the bottle that had a sharp, flat lip and a wide head. This shape increased the costs of making sealing disks as these disks had to be thick for such bottles. The wide head also gave more room for the gases in fizzy liquids to escape without properly sealing them. To counter this, Painter reshaped the bottle by making the lip of the bottle in a shape of a ring and making the head narrow, which allowed Painter to use a thinner sealing disk and keep the costs down as well. One can say Painter challenged the bottle manufacturers’ traditional bottle design to accommodate his invention. The plan to accommodate Painter’s invention was an issue in itself for the bottle manufacturers because the bottles had to be made according to certain specifications and had to be sealed in the right manner. This required enough force to seal the bottle. Painter responded by developing a “foot-powered crowner device” that made the sealing process efficient.

The second issue was the use of corks as a sealing disk. The problem was that high grade cork-wood was expensive. Painter’s solution was using a lower grade cork-wood. However, a lower grade cork-wood had “flinty” matter that was hard, and it could damage the metal cap with indentations when a high amount of pressure was applied to lock the caps on the bottle. Painter made alterations to the process of preparing corks by exerting a greater force to crush the “flinty” material. This made the sealing process easier by leaving no indentations on the bottle caps because the flinty material was crushed enough to make the finishing surface of the corks smooth.

The third issue was with the bottle sealing cap itself. High compressive forces were needed to seal the bottle, and it could neither be sealed nor opened by hand. A special device called the “bottle cap lifter”, later called bottle opener, was needed to open such bottles. Painter himself admits the disadvantage of sealing devices in his letter: “In as much as the application of my sealing caps involves powerful mechanism for compressing the disks and for bending or crimping the flanges of the caps into locking contact with bottles, it follows that considerable manual force must be applied for detaching the caps from the bottles.”[i] The design of the bottle opener used a sharp object that could slide between the bottom edge of the cap and the head of the bottle where force could be applied at various points to open the bottle with minimal effort. In 1894 Painter received a patent for the bottle opener and the combination of his inventions that meant fizzy drinks could be enjoyed at home with convenience.

The roadblocks that Painter encountered pushed him to come up with solutions to overcome the disadvantages in the design of his bottle-sealing device. A particularly interesting solution was the use of an adhesive which was “odorless, tasteless and practically insoluble” serving two purposes: to attach the sealing disk to the metal cap and to act as a protective layer from corrosion. While all this is easy to visualize today, as it’s very commonly seen, it was quite difficult to visualize this invention in 1891. This makes the figures used a valuable part of the patent description. They very accurately show the different aspects of packing such as the metal cap before and after being locked into the machine (figures 4 and 3), the sealing disk (figures 5 and 6), and the new bottle shape itself (figure 1 to 3).

The patent was awarded because it was radically new and very useful indeed. It later helped the beverage industry grow into major brands such as Coca-Cola. This invention was not obvious because Painter used metal caps in combination with a cheap cork used as an effective sealant. The metal caps in question were not very thick and could’ve been damaged if the cheap corks were not processed properly.

Painter was inventive and bold as he went against the established methods of bottle manufacturers of having a sharp lip and a wide head. His methods were vindicated because the invention successfully sealed the fizzy liquid contents and led to a new standard in drink bottle design. It was this invention for which he attained widespread attention and became wealthy, which led to the formation of Crown Cork and Seal Company that exists even today. I must say very few people go against convention, and we should be glad that he did. No one enjoys a flat soda.

By Jash Shukla

[i] “William Painter.” Lemelson-MIT, lemelson.mit.edu/resources/william-painter. Accessed 6th February 2018.