There are many things that we take for granted every single day. The floor we walk on is one of those things. How many times have you thought about the floor underneath you? Probably not even once! But the use of flooring in buildings is not a simple task. An engineer must account for potential energy absorption, load carrying capacity, durability and stabilizing agents when designing a specific floor plan for any specific building. This job has gotten a lot easier thanks to Cheng-Tzu Thomas Hsu, Sun Punarai, and Pedro R. Munoz from the New Jersey Institute of Technology. Their patent, “Composite Floor System Having Shear Force Transfer Member” aids engineers when they lay down flooring in multifamily housing, commercial buildings, and even hospitals.

The late Dr. Cheng-Tzu Thomas Hsu, Professor in the Civil and Environmental Engineering Department at the New Jersey Institute of Technology, alongside his former Ph.D. students Dr. Sun Punarari and Dr. Pedro R. Munoz, were granted this patent in August of 2010. This patent would later be similar to other patents, such as the ones originating from Nucor Corporation (US Patent # US8636456B2) and patents by Urbantech Consulting Engineering (US Patent # US9518401B2), that deal with the shear strength of flooring projects.

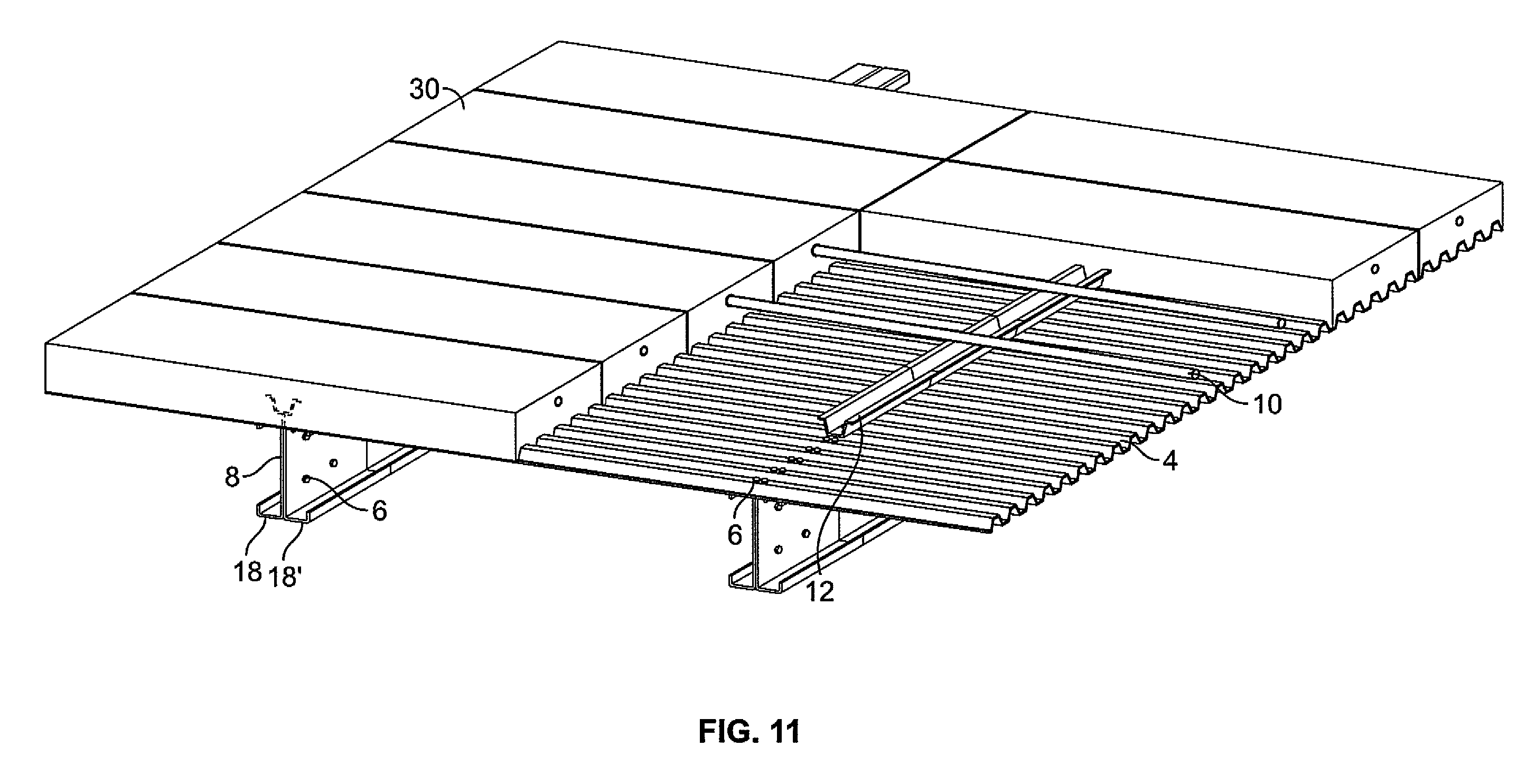

The common denominator amongst those three building types aforementioned is that they need tough flooring in order to withstand the day-to-day activities. Take a hospital for example; the flooring must be sturdy enough to withstand the weight heavy machinery, like an MRI machine PET and CT scanners, that are needed to make patients well. A “composite floor system” refers to a system that encompasses the use of multiple materials in the construction process of a floor system. In this specific patent, the composite floor system comprises of a slab, a deck material that is custom sized and shaped to support the slab, a support member attached to the deck material and a transfer member attached to both the slab and the deck. As you can see from the image, the slab and the deck are not simply placed on top of one another as most “non-composite” floor systems do. In this composite system, there is space in between the metal deck material and the actual flooring. This space, once embraced, will enable for an increase in the tensile strength which grants the floor the ability to carry much more weight.

This invention allows for more than just the ability of the floor to carry more weight. It grants engineers the capability of using lightweight materials that can easily be fabricated. These materials are incredibly easy to handle and transport, saving time and money all throughout a specific construction project. Moreover, this invention can minimize the need for expensive and sophisticated quality control measures that are needed to test a specific floor. Since this composite system can be put together off-site and then transported to the construction site, the floor system is capable of achieving the desired load capacity before even placed in the flooring of the building and thus saving massive amounts of time and money for construction workers.

“Composite Floor System Having Shear Force Transfer Member” has the capabilities of remodeling the process of construction across the spectrum. An increase in the desired weight carrying capacity of a floor can enable new types of architectural designs to lavish city streets. Most buildings today all look the same because they mainly follow the same concepts of building technologies. But with composite technology the potential of building marvelous architectural structures is a reality. If the central ideas behind a composite floor are implemented in walls and ceilings – which is currently in development and filed in the USPTO to be patented technology (see: US20140144091A1, “Composite wall panel, wall system and components thereof, and a method of construction thereof”) – structures will no longer have to be rectangular and a copy of the building next to it. Buildings can now be circular, triangular, hexagonal, etc. without giving up durability and stability.

The innovation of changing architectural designs is the fundamental contribution brought to society by this patent. Moreover, even though this particular patent is related to just the flooring system of construction, the focal point of the patent has the ability to flourish into something much larger than just flooring systems. A composite designed flooring system, with its light weight and durable characteristics can be used on transportation technologies such as airplanes and trains. Or used in elevators and moving walkways for the elderly. The potential uses of this technology could be seen in just about every imaginable structure in today’s society.

By Michael Tadros